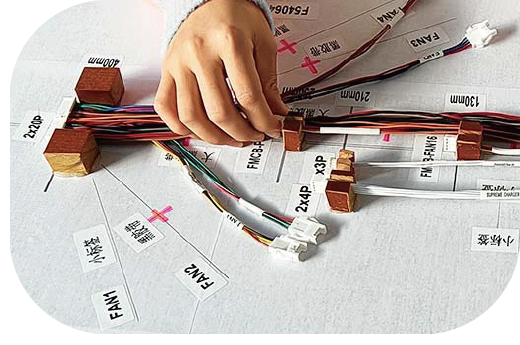

Customized Products

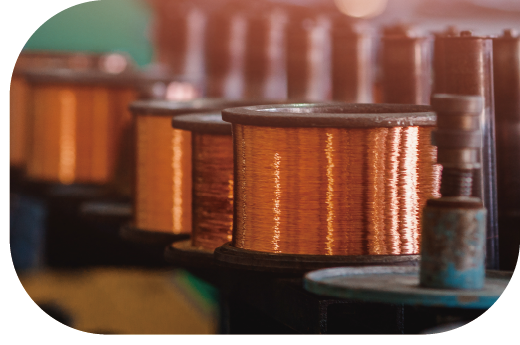

Bulk Cable

Supreme Charger designs and manufactures cables according to customers’ requirements, experienced with thermoplastics insulating, thermoset insulating and jacketing material, starting with the basic PVCs and polyolefins to highly specialized Fluoroplastics like FEP and TPE thermoplastic elastomers. (The highly specialized materials are used in plenum cables, industrial cables and cables that are exposed to hazardous environments, high temperatures and chemicals.)

We have military grade wire, silicone fiberglass wire, high temperature wire, silicone wire, teflon wire, XLPE wire, PVC wire, tube, thermocouple, heating wire, automobile wire, composite cable, and anti-refrigerant wire.

Design and manufacture cable systems that meet customer needs through vertical integration

Connectors

SC custom design reliable connector systems that will suit the requirements of many industries such as industrial, Marine and high speed data networks centers.

Applications:

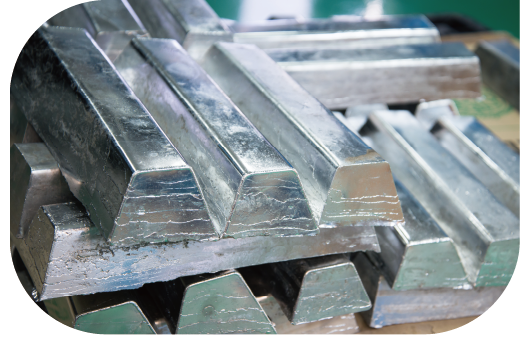

For connector components that are traditionally manufactured by machining, SC offers more economically precise solution when converted to die-casting. Consistently meeting tight tolerances over high volume production, our unique high-speed multi-slide die-casting process lends itself to the manufacture of intricate three dimensional connector housings and assemblies.

We utilize a broad range of state of art machines to die-cast larger complex connector components in zinc and aluminum.

Application:

Rubber Moulding: Injection Moulding / Compression Moulding / Transfer Moulding

Other Capabilities

Supreme Charger has an experienced engineering team and complete product solution which can design and manufacture cable system according to customers’ needs. Through vertical integration and supply chain management, SC maximizes customer value and gain competitive advantage in the global marketplace, we continue to provide excellent services to customers around the world.

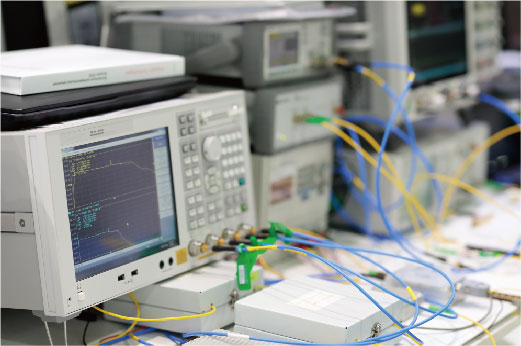

Professional Engineering

Product Testing

Supply Chain

Vertical Integration