Customer Requirements

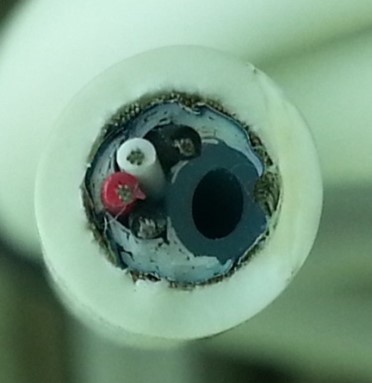

In today’s medical field, endoscopy is widely used, in addition to image transmission, therapeutic functionality is also required. Our customer, a medical endoscopy equipment manufacturer, ran into the problem that saline flushing was used through the empty tube that caused the backflow of saline and foreign objects from the optical channel to the handle, blockage at the tip, resulting in the loss of image and an increased risk of infection for patients. Therefore, the customer contacted SC to assist re-design the particular case.

Challenge Review

Because the endoscope contains an empty tube, Supreme Charger addressed the difficulties of sealing cable during production, preventing foreign objects and bacteria entering the cable during surgery, contaminating the endoscope, and causing patient infection. The endoscope can withstand the pressure and steam of high-pressure sterilization machines for repeated disinfection.

Supreme Charger Solutions

◢ Material Solutions: Medical-grade and certified PE, HDPE, PP & TPU materials are used in the updated design for replacement of previous parts.

◢ Process Solutions: All manufacturing and packaging processes are ensured in cleanroom throughout all stages. Supreme Charger continuously optimizes the design of molds and fixtures according to customer’s different endoscope diameter needs, in order to solve the problem of avoiding cable deformation caused by greater pressure during riveting and molding, resulting in endoscope diameter changes and blockages inside the endoscope. This achieved a tight connection process and non-permeable sealing.

◢ Testing Methods: Dimensional measurement, conductivity testing and high-pressure testing to ensure all processes are made properly for medical use, in order to meet our customer’s require and solving such problem.