Customer Requirements

A leader of automotive – parts manufacture has trusted Supreme Charger to provide cable assembly solutions for over a decade.

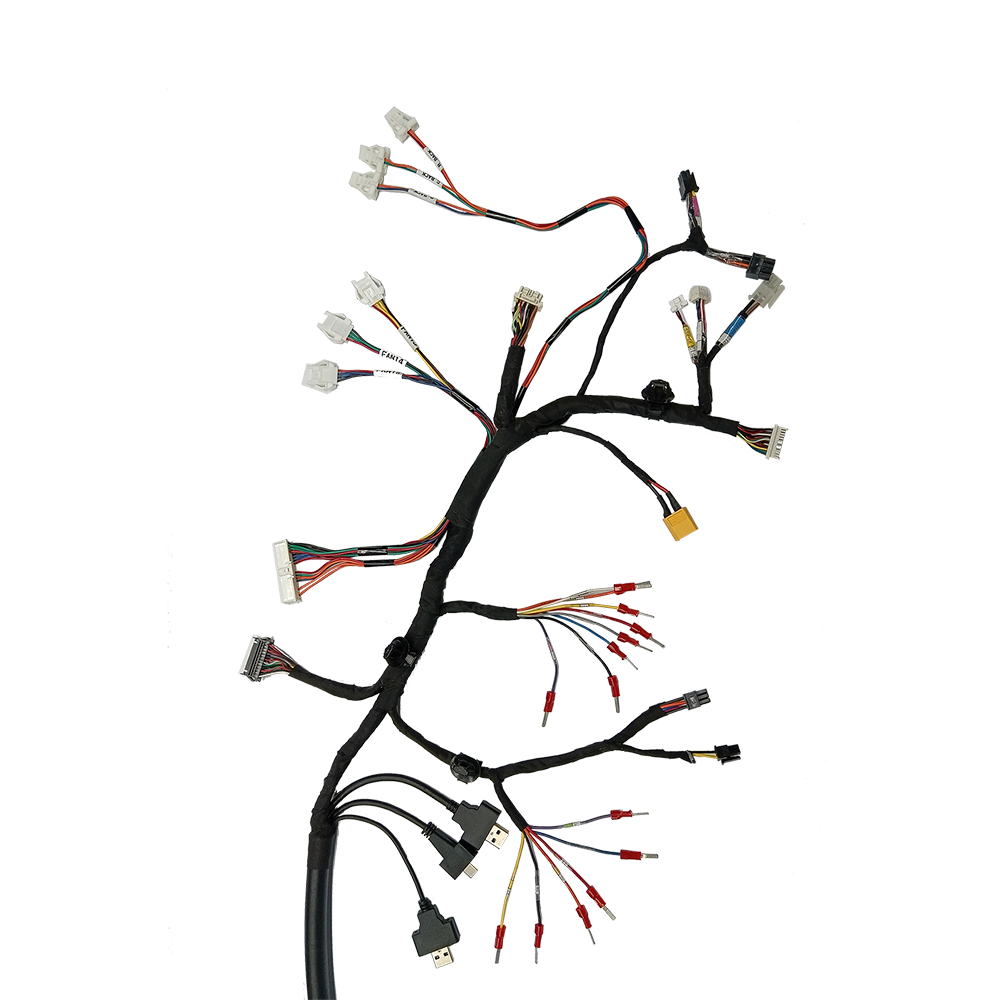

The customer originally approached Supreme Charger for improvements and lightweighting of the wiring harness for automobiles.

Challenge Review

Supreme Charger’s task was to design a set of cable assembly that brought together several control parts to make the circuit well constructed while reducing its total weight. The solution for such harness had to be structurally more stable and manufacturable under customer’s request.

Supreme Charger Solutions

Supreme Charger combined wire harnesses, electronic components, and connectors- including electronic wires, USB2.0 cable, USB3.0 cable, and motion sensors, as we design these parts into a combination of harness. Our design improved the electrical performance while reduced its weight, making the combined wire harness more refined while perform at its best quality.

We have also successfully developed USB2.0 A, USB3.0 A, and USB C TYPE with screws to improve the stability of the wiring harness assembly. At the same time, the use of wires is reduced, thereby helping customers reduce the cost of molds and equipment, most importantly, lightened its total weight due to the total wire volume along with shortened wire length. The solution optimized the product function and standardized such accessory, making the wire harness perform better than its original version yet with more advanced workmanship.